All Products

Dry Lubricant

REPELS DUST AND DIRT WITH NO OILY RESIDUE. Ideal for protecting tools and parts where dust and dirt collect, like your garage. Quick dry with no mess. Perfect for window, door, and drawer tracks. Lubricates with no oily residue. Dries fast. Resists dust and dirt. 50-state compliant. Features state-of-the-art Cerflon® solid lubricant for superior durability and long-lasting lubrication.

Drum Lifting Hook

Drum Lifting Hooks: Drum Lifting Hook is designed to lift 55-gallon steel drums with rims on both ends. 42 Series Heavy-Duty Below-Hook Lifters ONLY for a 55-gallon (210 liter) steel drum. Two Lifting Modes: 1) Horizontal mode 2) Off-Vertical model enables you to upend, and set a drum down on its side.

DIELECTRIC ANTI-SEIZE GREASE (L803)

Liquid Wrench® Dielectric Anti-Seize Grease is a dual-purpose, synthetic, non-drying dielectric paste and anti-seize compound; formulated with a balanced blend of lubricating solids, rust and corrosion inhibitors, homogenized into a non-melting grease carrier. Works as both an anti-seize and a dielectric grease. Meets Military Specification MIL-A-907E. Designed as a unique preventative maintenance tool providing complete parts protection on threaded fittings and all metal surfaces subjected to harsh environments or high temperatures to 1,800°F. Chemically inactive, waterproof, with high dielectric properties; it is an excellent material for protecting electrical parts and assemblies such as connectors, disconnect junctions, terminals, ignition systems, cable connectors, and battery terminals. Compatible with most rubbers, plastics, and ceramics; it is a superior lubricant for O-rings and gaskets. Excellent high-temperature properties help prevent fusing of bulbs to sockets. Not recommended for use in pure oxygen and/or oxygen-rich systems. Not for use as a sealant for chlorine or other strong oxidizers.

Diamond Ripper Rescue & Mini-Ripper Blades

Best performance, long life, incredible value. Cuts steel, concrete, correctional glass, and much more. Double-layer diamonds in a vacuum-brazed nickel matrix. Solid core 4.5”, 7”, 12” and 14” blades can’t break (16” blades have laser-welded cutting edges). 9” blade is new for 2017. Diamond Ripper fits gas saws with 20mm and 1” spindles; Mini-Ripper fits 7/8” and 5/8” grinders.

Devcon® Zip Patch™

High-technology, adhesive-impregnated patching system that cures at room temperature and makes permanent, waterproof field repairs to pipes, tanks, and containers. Easy-to-use, fast-setting patch kit. Hardens to a tough, durable waterproof finish in minutes. Excellent adhesion to iron, steel, stainless steel, titanium, fiberglass, aluminum, wood, ceramics, composites, acrylics, PVC, and most other plastics. Minimal surface preparation required.

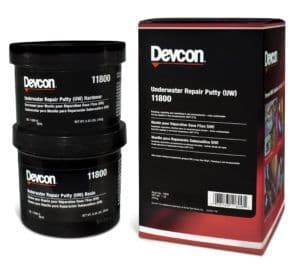

Devcon® Wet Surface Repair Putty (UW)

High-performance technology for repairing, patching, and rebuilding equipment in habitually wet environments, including underwater. Penetrates wetness to bond securely to steel, iron, aluminum, brass, bronze, concrete, wood, and some plastics. Invaluable for use in pulp and paper mills, wastewater treatment plants, and marine environments. Eliminates the need for substrate to be thoroughly dry before repair.

Devcon® Wear Resistant Putty (WR-2)

Smooth, non-rusting, all-purpose epoxy putty for repairs requiring low-friction finishes, such as machine lathe beds. Bonds to steel, iron, aluminum, ceramic, concrete, brass, and some plastics. Contains wear-resistant fillers for low friction applications. Also available in liquid form.

Devcon® Titanium Putty

High-performance, non-rusting titanium-reinforced epoxy engineered for making repairs to machinery and equipment that can be precision machined. Withstands heavy loads in hard chemical environments. Excellent temperature resistance (350°F). High compressive strength (15,200 psi). Resistance to chemicals and most acids, bases, solvents, and alkalis. Qualifies under Mil Spec MIL-PRF-24176C, Type I. Listed under NSN stock #8030-01-335-0562.

Devcon® Stainless Steel Putty (ST)

Stainless steel-filled epoxy putty for patching, repairing, and rebuilding stainless steel food processing equipment. Non-rusting formula that bonds to ferrous and non-ferrous metals. NSF-certified for potable water applications and acceptable for use in meat and poultry plants.